Stationary feed mixers solve the tasks on the spot. The applications are different. Whether cramped conditions or the need for integration into existing plant technology (such as belt feeding systems).

Stationary mixer wagons by BvL with one or two mixing augers. Our stationary mixer is available with capacities between 6.5 and 30 m³.

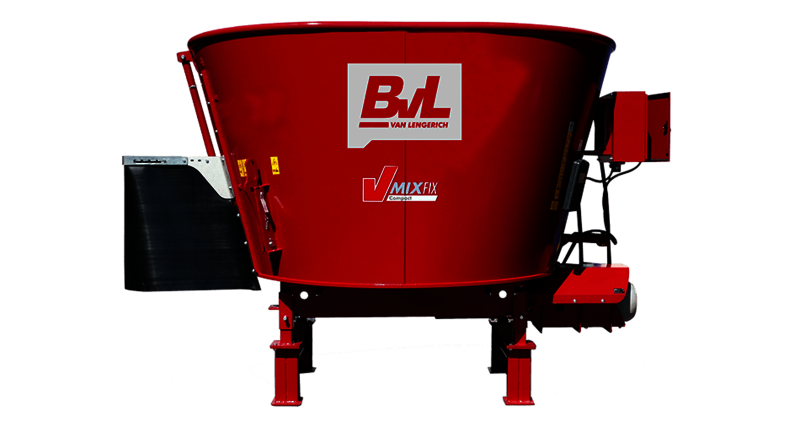

V-MIX Fix stationary mixers

Stationary mixer

A mobile mixer wagon may not prove to be the best solution for every agricultural business. However, every farm definitely wants a feed mixer. Mixing feed right then and there – that is made possible by the stationary mixer V-MIX Fix Plus made by BvL. Whether it is used as a feeding system for automatic feeders, as a processing unit for straw pelletization or other stationary applications - the stationary mixer can be perfectly adapted to the specific requirements and conditions of every barn.

Auger matched perfectly with the hopper

Whether it is fitted in a 1- or 2-auger mixer - the power mixing auger is the centerpiece of the stationary mixer V-MIX Fix. It sets itself apart with the smooth and gentle way it mixes the material loaded into the mixing hopper. This careful mixing process preserves the structure inside the feed to the best possible degree. The power mixing auger of the stationary mixer is adapted perfectly to the shape of the mixing hopper - as small as possible, but as large as necessary. This design makes it possible to utilize the full volume of the mixer wagon - regardless of the usable capacity - without the need to cut back on the required quality of the mixture. This helps save both time and money. By the way: The power mixing auger can be optimally adjusted to various types of feed by adjusting the knives.

Why is the structure of the feed so instrumental?

The feed needs to have structure to allow the cattle to ruminate properly. Structure is what helps maintain the optimum pH value in the rumen. What is more, structured feed lowers the risk of such health problems as displacements of the bovine abomasum, and it boosts feed intake and improves overall feed conversion efficiency.

No spilling, please

Just like all other BvL mixers the stationary mixer V-MIX Fix comes standard with a welded-on anti-spill ring. This fixture keeps the mixed material from spilling over the edge of the hopper during mixing. Since this mixer is set up stationary, spilled material would be a particular nuisance and tedious to remove. As an added benefit, the structure forms a finishing piece to the hopper that makes it exceptionally stable.

Combine discharge options as you need them

Stationary mixers made by BvL can be equipped with a host of different discharge systems. The available options allow you to dispense the feed through a discharge opening on the side using BvL's patented EDS (Exact Dosing System) or combine the discharge with others systems by means of elevators, e.g. the special feed conveyor developed by Eder GmbH. The stationary feed mixer – set up immediately in front of or inside the barn – can be used to unload green or mixed feed directly onto the 100 m feed conveyor. This feed conveyor will then transport the base feed directly to the animals. Another excellent resource for first-class advice in the field of automated feeding is our partner Fjøssystemer.

Emptying mode

What happens after the feed has been discharged? The optional emptying mode developed by BvL can then be used to cleanly drain the mixer by flinging any leftover feed off the mixing auger. This option provides the farmer with an easy and convenient way to prepare the mixer for the next load and ensure that the stationary mixer is drained properly and completely.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/9/3/csm_bvl-futtermischer-v-mix-fix-65-14-1s-freisteller_fd5c9da637.png)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/6/0/csm_bvl-farmtechnology-product_photo-V-MIX_Fix_20H-2S_RGB_58c6c75e46.png)